Why Have We Accept and Establish Aerospace Standards for Our Business Ethic?

Quality

HSF believes that accuracy is of absolute importance in the machining and fabrication of aerospace and aircraft parts, which require the highest level of performance under very high stress conditions during flight.

Traceability

HSF’s extensive level of experience provides clients and strategic partners with our assurance that the high precision parts will meet their precise specifications and performance standards.

Our Main Discipline

At HSF, we deliver the highest quality products and services, and we strive to get it right the first time. We continuously improve our performance and processes to ensure we meet or exceed our customers’ expectations.

Acceptance Quality Limit (AQL) at HSF:

In-House AQL Control

HSF does not interpret the sampling requirements contained herein as allowing defective parts (AQL Levels) to be sold to the customers.

Customer Satisfaction

HSF accepts and applies that all supplied parts must comply with all requirements of the Purchase Order, Applicable Standards, Engineering Drawing and / or product description requirements.

AQL Levels We Have Applied

HSF applies 3 levels for AQL:

Critical Characteristics: 100% Inspection shall be assigned unless otherwise specified.

Major Characteristics: 0.65% AQL Level shall be assigned unless otherwise specified.

Minor Characteristics: 2.5% AQL Level shall be assigned unless otherwise specified.

Quality Control and Process Approval

Independence

Our business discipline is based on fully independent control and validation of all processes and tolerances based on international standards and customer requirements.

International Standards

Our quality control laboratory can with fully independent quality and process approval discipline apply the Non-Destructive and Destructive Testing procedures. In-house and external all stage approvals are managed with AQL limits by quality control laboratory.

Customer Approvals

Client confirmation and approval is main and only approval condition for the contracts. This is all documented through our quality management system and ERP that are tailored to fit our customer’s shipping documentation and quality record requirements and certifications.

HSF produces expertly designed, high-quality, complex machined components and products. Our investment in training and obtaining the latest approvals and certifications provides you with an exceptional level of service and compliance. Current approval levels include ISO 9001, AS9100 rev D, and ISO-EN 17025 compliant.

Our quality control laboratory can with fully independent quality and process approval discipline apply the Non-Destructive and Destructive Testing procedures. In-house and external all stage approvals are managed with AQL limits by quality control laboratory.

One of the most important factors when manufacturing parts for aircraft or related systems is safety. There is no room for human or any foreign object error in the production and assembly of an aircraft. From the smallest interior detail to the plane’s exterior, any flaws or inconsistencies can have devastating effects.

All devices and equipment used in HSF production and quality control processes are periodically calibrated, and all calibration records are kept in the ERP system. Policies that prevent the participation of uncalibrated devices or equipment in the production and quality control processes have been developed and are actively implemented.

IN-HOUSE QUALITY CONTROL CAPABILITIES (designed according as ISO-EN 17025 & AS9003A) (updated on 23.02.2024)

All test and measuring devices including the hand tools are periodically calibrated and reported.

| # | DEPARTMENT | TEST TYPE | MACHINE / DEVICE | DATE of MANUFACTURING |

|---|---|---|---|---|

| 1 | Laboratory | NDT | Coordinate Measuring Machine | 2020 |

| 2 | Laboratory | NDT | Computer Controlled Video Measuring Machine (2 units) | 2019 - 2024 |

| 3 | Laboratory | NDT | Computer Controlled Profile Projector (2 units) | 2019 - 2024 |

| 4 | Laboratory | NDT | Optical Emission Spectrometer | 2021 |

| 5 | Laboratory | DT | Computer Controlled Tensile Strength Test Device - 600kN | 2019 |

| 6 | Laboratory | NDT | Desktop Digital Hardness Test Device (4 units) | 2020-2024-2024-2024 |

| 7 | Laboratory | NDT | Desktop Analog Hardness Test Device (1 unit) | 2024 |

| 8 | Laboratory | NDT | Portable Hardness Test Device with Leeb and Pen Probes (2 units) | 2024-2024 |

| 9 | Laboratory | NDT | Desktop Automatic Micro Vickers Test Device | 2021 |

| 10 | Laboratory | NDT | Salt Sprey Test Unit | 2024 |

| 11 | Laboratory | NDT | Drying Oven | 2023 |

| 12 | Laboratory | NDT | Eddy Current (IACS %110) | 2024 |

| 13 | Laboratory | NDT | Ultrasonic Flaw Dedector (2 units) | 2019 - 2024 |

| 14 | Laboratory | NDT | Surface Roughness Measuring / SRM | 2021 |

| 15 | Laboratory | NDT | Coating Analysis Measuring Device | 2020 |

| 16 | Laboratory | NDT | Metallurgical Measuring Microscope | 2020 |

| 17 | Laboratory | NDT | Objective Measuring Microscope | 2019 |

| 18 | Laboratory | NDT | Sample Preparing Unit for Microvickers and Metallurgical Microscope | 2020 |

| 19 | Laboratory | DT | Computer Controlled Fastener Torque Tension Test Machine | 2024 |

| 20 | Laboratory | DT | Programmable Temperature and Humidity Testing Chamber | 2024 |

| 21 | Laboratory | DT | Computer Auto-Controlled Impact Tester 150/300J | 2024 |

| 22 | Laboratory | DT | Computer Controlled Coulometric-Electrolytic Multi-Layers Thickness Gauge | 2024 |

| 23 | Laboratory | NDT | Computer Controlled Roughness and Waviness Tester (+/- 1000 µm) with Inner Hole and Thread Measurement Sensors | 2024 |

| 24 | Laboratory | NDT | Permeability Meters (ASTM A342) for Magnetic Materials | 2024 |

| 25 | Laboratory | NDT | Liquid Penetrant Testing | |

| 26 | Laboratory | NDT | CAD-CAM Softwares (3 apps) | |

| 27 | Laboratory | NDT | Desktop - Water Quality Test Unit (Temperature, Salinity, PH, TDS) | 2024 |

| 28 | Laboratory | NDT | Portable - Water Quality Test Unit (Temperature, Salinity, PH, TDS) | 2024 |

IN-HOUSE PRODUCTION PROCESS CAPABILITIES

PROCESS CONTROL & APPROVAL & REPORTING

International Standard: AS9100 Rev.D Requirements;The ERP and MRP systems are designed according as AS9100 International Standards' requirements, can provide the following capabilities:

- Process Management,

- Process Approval,

- Process Reporting,

- Risk Management,

- Supplier & Customer Management,

- Failure Management,

- Corrective Action and Root Cause,

- Internal Audits and Management Review.

CNC MACHINERY CAPABILITIES

HSF precision processing capability includes CNC Lathe, Vertical Machining and Swiss Lathe units that offer the highest quality components and fasteners using an array of alloy steels, alloy nickels and titanium alloys in a wide variety of tolerances. Our CNC machinery process has Laser Marking, Dot Matrix Marking and Packing Sealing and Heating units.

COMPUTER CONTROLLED MICRO-LASER WELDING UNIT

Continuous Laser Source: 2000 W,

Control System: Four-Axis Micro Control

Welding Line Size: 500*300*300 with 1000*800 working table.

VACUUM HEAT TREATMENT CAPABILITY

Working Temperature: 2250 Fahrenheit (1400 Celsius),

International Standard: AMS 2769 Rev. D,

Chamber Size: Depth400 * Width300 * Height300mm (36Litre).

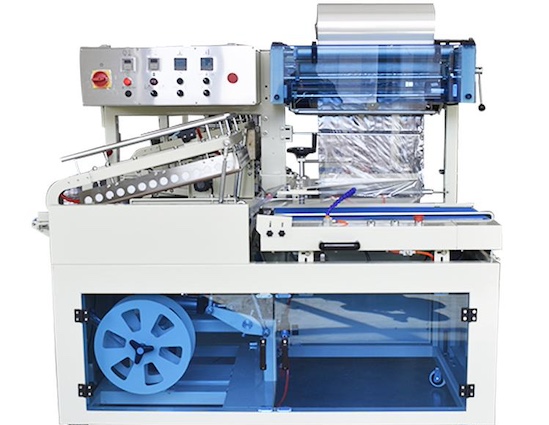

AUTOMATIC LABELLING & PACKAGING LINE

Box Sealing Capability: 500*600mm

Thermal Shrink Capability: 600*500mm

Tunnel Size: 1200*400*200mm

Box Strapping Capability: 800*600mm

Heating Line (Adjustable): 6.5KW

EDDY CURRENT - IACS (International Annealed Copper Standard) CAPABILITIES

100% IACS is equivalent to a conductivity of 58.108 megasiemens per meter (MS/m) at 20°C or a resistivity of 1/58.108 ohm per meter for a wire one square millimeter in cross section. IACS % = (172.41/resistivity) where resistivity, ρ,(ro) is in micro-ohms per centimeter.

| ELEMENT | DOWNLOADABLE VERSION |

|---|---|

| Aluminum Alloy (Wrought) | (% IACS) and (Ohm-m) |

| Copper Alloys | (% IACS) and (Ohm-m) |

| Steel Alloys | (% IACS) and (Ohm-m) |

| Stainless Steel & Super Alloys | (% IACS) and (Ohm-m) |

| Nickel & Titanium Alloys | (% IACS) and (Ohm-m) |

| Magnesium Alloys | (% IACS) and (Ohm-m) |

SURFACE ROUGHNESS MEASUREMENT

ISO 21920-1/2/3 2021-12 (Geometrical Product Specifications)

Application: Thread Precision Measuring

Acceptance Rule: 16 % tolerance acceptance rule (T16%)

Procedure: If the "T16 %" symbol is indicated,

the 16 % tolerance acceptance rule shall be applied. The requirement

is fulfilled and the testing process may be stopped when:

1. the first measured value does not exceed 70 % of the specified upper

tolerance limit value or the first measured value does not go below 130 % of the specified lower tolerance limit value;

2. the first three measured values do not exceed the specified upper tolerance limit value or the first

three measured values do not go below the specified lower tolerance limit value;

3. no more than one of the first six measured values exceeds the specified upper tolerance limit value

or more than one of the first six measured values goes below the specified lower tolerance limit value;

4. no more than two of the first 12 measured values exceed the specified upper tolerance limit value

or more than two of the first 12 measured values go below the specified lower tolerance limit value.

Otherwise, the workpiece shall be rejected.